Conical Refiner

Conical Refiner provides gentle yet effective fiber treatment for various applications.

Conical Refiner provides gentle yet effective fiber treatment for various applications.

The Parason Conical Refiner delivers low-intensity, high-efficiency fiber development through its advanced conical refining geometry—enabling superior fiber bonding while minimizing energy consumption and fiber damage.

Engineered for modern stock preparation systems, the Conical Refiner provides gentle yet effective fiber treatment that improves paper strength, formation, and dewatering characteristics across a wide range of fiber furnishes and paper grades.

Progressive conical zone ensures even fiber exposure across the entire refining surface.

Develops fiber bonding potential without excessive cutting or mechanical damage.

Optimized flow dynamics deliver significant energy savings compared to conventional refiners.

Consistent refining action ensures repeatable quality across production runs.

Revolutionizing Refining Efficiency

A Next-Generation Solution for Refining

The Parason Confiner embodies a refined approach to fiber development—combining proven conical geometry with advanced flow engineering to deliver superior refining performance.

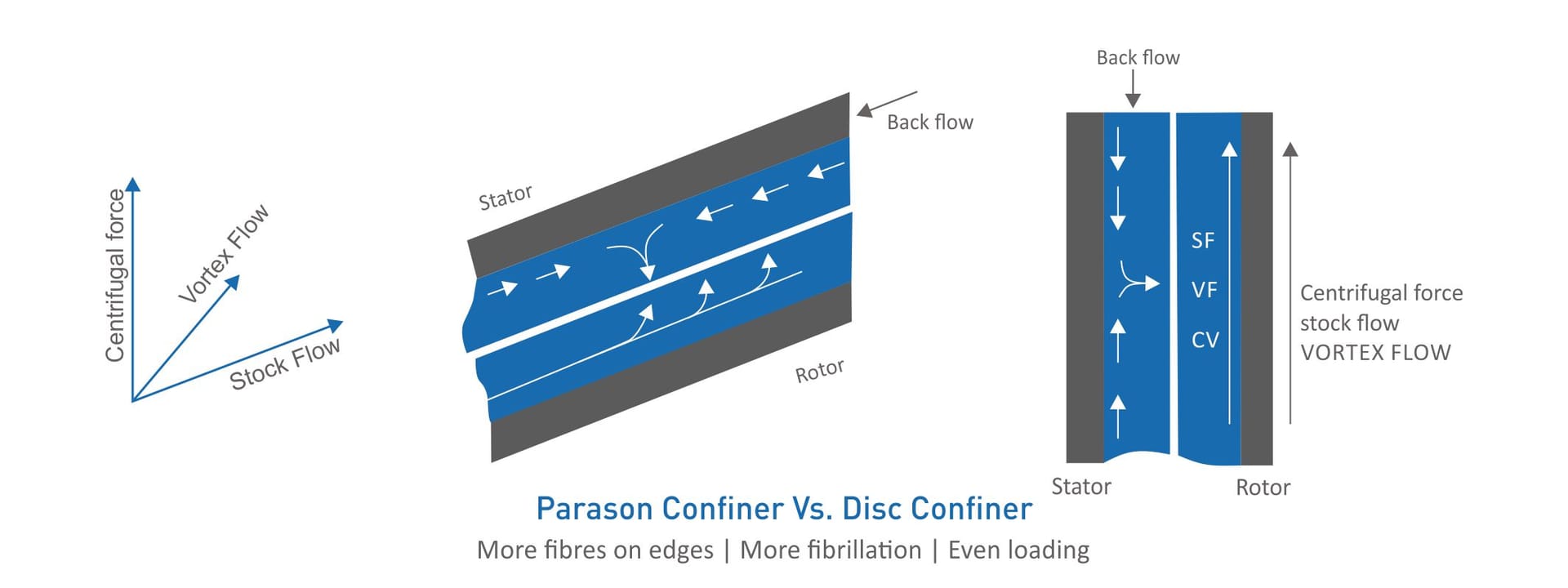

Parason Confiner Vs. Disc Confiner — More fibres on edges | More fibrillation | Even loading

The progressive conical geometry creates a natural flow path where fibers undergo gradual, controlled treatment—developing bonding potential through fibrillation rather than aggressive cutting.

Centrifugal flow dynamics ensure fibers are evenly distributed across the refining zone, while precision gap control maintains consistent treatment intensity throughout operation.

Tangential inlet design and optimized chamber geometry deliver stable hydraulic conditions, ensuring predictable refining results regardless of throughput variations.

Low-intensity treatment philosophy preserves fiber length and strength properties while maximizing inter-fiber bonding for improved paper quality.

Designed for continuous industrial operation where uptime matters and maintenance windows are limited.

Space-efficient design allows easy retrofit into existing stock preparation lines.

Cantilever construction enables quick rotor and stator access for maintenance.

Simplified loading system reduces filling change time significantly.

Heavy-duty bearings and robust construction ensure reliable long-term operation.

Parason manufactures precision-engineered confiner fillings using advanced 4-axis CNC machining, ensuring exceptional accuracy and consistent refining performance across all fiber applications.

The Parason Confiner is engineered for today's connected mill environments, supporting advanced automation and digital transformation initiatives.

Designed for seamless integration with DCS and PLC-based mill control systems.

Advanced loading system enables accurate, repeatable gap adjustment for consistent results.

Compatible with Industry 4.0 monitoring and predictive maintenance platforms.

Key specifications at a glance

Detailed specifications and custom configurations available upon request. Contact our technical team for your specific application requirements.

With decades of refining technology expertise, Parason has earned the trust of paper manufacturers across six continents. Our commitment to precision engineering and application-specific solutions ensures reliable performance and lasting partnerships.

Discover how the Parason Confiner can improve fiber development, reduce energy costs, and enhance paper quality for your specific application.